- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

FLIFT 10 ton capacity forklift

Date: 2024-11-04 View:

Maximize productivity and tackle heavy loads with ease. Explore its features now!

10 Ton Diesel Forklifts play an essential role in industrial handling. Boasting robust power and exceptional carrying capacity,

these forklifts have quickly become indispensable tools across many industrial fields.

10 ton diesel forklifts can be an invaluable tool in manufacturing industries, used to move raw materials, parts and finished products around.

Automobile plants use this type of forklift regularly in handling large body frames, engines and other heavy components;

similarly in logistics/warehousing operations where cargo handling, stacking and handling play an integral role - whether at large warehouses,

ports or stations where forklifts play an instrumental part of cargo transfer operations.

FLIFT 8-10 tons diesel counterweight forklift is an outstanding example.

Equipped with an air filter equipped with safety filter element and equipped with electronic pressure alarm for safer and more reliable engine intake volume control,

its split type radiator has better heat dissipation effect as well as reliable heat balance of the entire machine.

Standard power braking system features strong braking ability while emergency braking reliability can be increased by selecting large-capacity bag accumulator with outstanding performance,

while full hydraulic power steering ensures flexible yet stable turning with high reliability.

Practical applications of 10 tons diesel forklifts reflect their immense value in everyday life. Within factories,

forklifts can efficiently move production equipment and raw materials for improved production efficiency;

within warehouses they allow fast loading/unloading/stacking operations which help ensure smooth logistics flow;

finally within stations/docks/ports etc they help shoulder heavy cargo handling tasks providing solid guarantees for economic development.

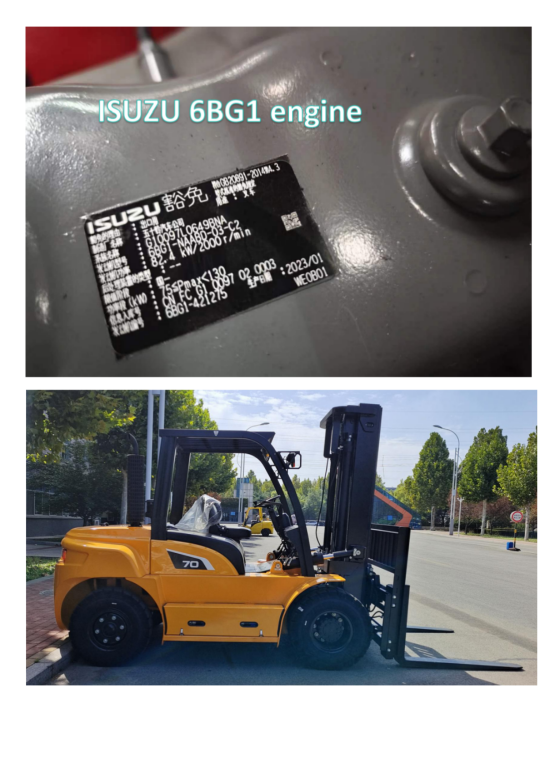

Second, powerful power configuration

(A) An array of optional engines: The 10 ton diesel forklift truck offers an abundance of engine options,

with Isuzu and Cummins engines from Japan serving as its centerpiece.

Isuzu engines are well known for their exceptional quality and dependability, both qualities that serve them well in automotive sectors such as forklifts.

Their diesel engines produce high torque at lower RPM which works to their advantage when starting and climbing hills.

At the same time, Isuzu engines use VGS variable section turbochargers which can be adjusted according to engine speed using a control diaphragm diaphragm

to open and close blades so as to maintain optimal power output at all times.

Isuzu diesel engine high pressure common rail injection system features an injection pressure of 180MP,

composed of electronic control unit, high pressure pump, tubing common rail tube and electronic fuel injector.

Flexible adjustments of injection pressure, timing rate and accuracy enable easy set-up and usage.

With pre-injection up to five injection points and pre-injection capabilities for multiple injectors available at high injection pressure levels it significantly lowers NOx and particulate emissions emissions.

Cummins engines offer numerous advantages.

First and foremost is its impeccable reliability and durability;

high-grade materials and advanced manufacturing processes are used during design and production to ensure safe performance under varying environmental conditions.

Second, to achieve improved fuel economy and lower operating costs, employing advanced fuel injection technology and combustion chamber design can significantly lower operating expenses.

Cummins engines feature innovative emission control technologies such as particle filters and selective catalytic reduction to achieve low emissions in line with stringent global emission standards.

Cummins QSF3.8 fully electronically controlled engine is specifically tailored for internal combustion forklifts that weigh 5-10 tons,

featuring high strength design that can handle high strength operation; rear gear chamber transmission system provides higher suspension stiffness and noise reduction;

high strength cast iron cylinder block with an etching design to maintain maximum strength while simultaneously reducing dead weight;

use of lightweight yet high quality composite materials provide higher power-to-weight ratio; Under equipment requirements,

custom curves with low speed, high torque, good transient response and acceleration optimization capabilities should be provided to increase acceleration and overall machine efficiency.

Adopt a cutting-edge electronic control module and intelligent electronic control technology,

integrate with the entire machine and optimize performance and fuel savings effects while providing multifunctional electronic control guarantees,

self-diagnosis monitoring protection ability that are safe, reliable and easy to operate.

In summary, both Isuzu and Cummins engines of 10 tons diesel forklift trucks offer unique characteristics and benefits to suit a range of user applications.

They give users access to various power solutions for meeting varying use requirements.

Third, customized door frame and fork.

(1) Customizable Lifting Height Of The Door

The lifting height of a 10 tons diesel forklift door can be customized, and maximum can reach 6 meters. Utilizing three-section full free gantries has numerous advantages,

especially meeting different working scenarios' height requirements; in warehouse environments this high lifting height enables goods to easily be placed onto upper shelves,

increasing space utilization rate significantly; for large logistics centers the maximum lifting height can directly stack goods on high shelves without additional handling steps reducing work efficiency significantly.

(2) Customizable Fork Length

A 10-ton diesel forklift usually uses a standard fork of 1520mm; however, its length can also be altered according to individual operation needs and tailored as necessary for full satisfaction of various requirements.

Typically speaking, standard fork length ranges between 1.22 meters and 2.2 meters in terms of length standard while its width

and thickness of the 10-ton forklift typically measure 150 mm and 60 mm respectively - however these dimensions may differ depending on different operation scenarios

which necessitate different requirements regarding fork length requirements.

Customizing longer forks can make moving longer goods more efficient, such as wood processing plants that must carry longer boards, for instance. Furthermore,

shorter forks may provide greater flexibility and simplicity of operation in certain operating environments where space may be at a premium.

Shortly put, the 10-ton diesel forklift truck's door lifting height and fork length can be customized on demand to give users more choices and meet different working environments and needs.

Furthermore, four efficient pitch fork devices are also included with each fork.

1) Pitch Fork Device of Forklift Is Important

Forklift standard pitch fork devices play an essential part in actual operation.

They enable forklift drivers to flexibly adjust fork spacing without leaving their seats -

for example when handling goods of different specifications that traditionally required drivers to get off and adjust manual fork spacing manually which consumed time,

energy and reduced work efficiency. With pitch fork devices they are much simpler for use and save both time and energy while increasing work efficiency.

The pitchfork device also helps prevent cargo and pallet damage during handling. If fork spacing is inadequate during this process, goods could tilt and slip, potentially resulting in damage to goods and pallets.

With accurate adjustment according to product size, pitch fork ensures goods remain stable during handling while simultaneously decreasing their risk of damage.

According to relevant data, using a pitch fork device can reduce damage rates for goods and pallets by more than 30% while increasing work efficiency to bring down operating costs of enterprises.

An example would be in a logistics center where moving large numbers of goods may take more time and manpower with traditional forklifts than with one equipped with pitch forks equipped with pitch fork devices -

ultimately saving labor costs as well as equipment operating costs.

Simply stated, the 10-ton diesel forklift standard pitch fork device's ability to quickly adjust fork spacing has greatly enhanced work efficiency

while simultaneously minimizing goods damage, reaping significant economic rewards for enterprises. 5. Unique product features

(1) Outstanding Performance

The FLIFT brand 10 ton diesel forklift offers outstanding power performance. Thanks to advanced engine technology, its stability under heavy load conditions remains reliable. Furthermore,

its power output is strong, easily meeting any operational environment complexity; such as when handling large goods. Furthermore, when quick starting or acceleration are required for increased work efficiency.

FLIFT brand 10 tons diesel forklift has been appropriately optimized in terms of its cooling system. Heat dissipation performance has been significantly enhanced, which improves reliability across key components such as transmission and engine.

Even under continuous operation for extended periods, its temperature-regulating abilities ensure proper working temperatures that ensure regular operations of this forklift.

Safety and reliability are top priorities on the FLIFT brand 10-ton diesel forklift. When equipped with an integrated modular electrical box, protection levels can reach IP56;

improving safety and maintenance ease for electrical systems. In addition, new sealing gasket technology was recently employed to address oil seepage issues of oil tank caps while simultaneously reducing security risks.

(2) Reasonable Ergonomics

The ergonomic design of the FLIFT brand 10-ton diesel forklift truck is very accommodating, featuring suspension cab technology to further minimize vehicle vibration and create a more conducive working environment for its driver. Furthermore,

fully sealed cockpit and instrument panel help reduce driver ear noise levels as well as sound power levels as well as dust and noise interference issues.

Additionally, wide field of view lifting systems and wide Angle mirrors drastically expand a driver's field of view.

They enable him to see clearly his working environment for improved safety of operation.

When equipped with CAN bus instruments with LCD screens they allow real time monitoring of engine status through LCD screen display which facilitate timely grasping operation of forklift.

(3) Convenient Maintenance

The FLIFT brand 10 ton diesel forklift offers outstanding ease of maintenance with external transmission oil filters and hydraulic return oil filters with external structures making cleaning and replacing more convenient and faster,

saving both service time and costs. Maintenance personnel can quickly clean or change filters as required, decreasing service times and costs significantly.

Interior space of car body increased, optimized parts layout optimized, maintenance space expanded and ease of maintenance improved.

Hood opening Angle was increased from 70deg to 80deg, making it easier for maintenance personnel to inspect and repair key components like engines.

Independent integrated electric control box reduced electrical failure rate significantly as daily inspection and maintenance was made more convenient and improved Forklift truck warranty warranty protection was ensured.

Warranty Period (2000 hours or 2 years whichever comes first).

Warranty periods are an integral factor when choosing forklift products,

and our 10 ton diesel forklifts come equipped with two year or 2,000 working hour warranties to reassure users about their quality.

FAQ

1. How much does a 10-ton forklift weigh?

A standard 10-ton forklift typically weighs around 13000kg , equip with 2 stage 3m mast and 1520mast. depending on the model and configuration.

If add the enclosed cabinet and air conditioner device, maybe increase 500-600kg weight.

2. How high can a 10-ton forklift lift?

Most 10-ton forklifts can lift loads up to approximately 12 to 20 feet (3.6 to 6.0 meters),

If lift up to the maximum 6m mast, must equip with the 3 stage mast to ensure the safety.

3. What is the maximum weight that a 10-ton forklift can lift?

The maximum weight capacity of a 10-ton forklift is generally around 22,000 pounds (10,000 kg), as 10 tons refers to its lifting capacity.

As usually our FLIFT 10ton diesel forklift holds the 20% overload capacity. So the maximum lifting capacity around 12000kg

(in the case of under the 2m lifting height)

4. Are there different types of 10-ton forklifts?

Yes, there are various types of 10-ton forklifts including diesel, electric, and propane-powered models tailored for different applications.

The 10t electric forklift series owns two types, one is traditional lead-acid battery , another is the very high efficiency iron lithium battery forklift.

we dive deep into the robust features of the FLIFT 10-ton diesel forklift.

Discover how its powerful engine and advanced hydraulic system make heavy lifting effortless in any industrial setting.

We’ll showcase real-life applications and demonstrate its unparalleled efficiency on the job site.

Don’t miss out on seeing this powerhouse in action! Click to watch now and elevate your material handling knowledge!

.png)