- Diesel Forklift

-

- 4.5 Ton Diesel Forklift48 Ton Diesel Forklift3 Ton Diesel Forklift3.5 Ton Diesel Forklift2.5 Ton Diesel Forklift33 Ton Diesel Forklift15 Ton Diesel Forklift10 Ton Diesel Forklift8 Ton Diesel Forklift4 Ton Diesel Forklift6 Ton Diesel Forklift2 Ton Diesel Forklift1 Ton Diesel Forklift1.8 Ton Diesel Forklift1.5 Ton Diesel Forklift6 Ton Diesel Forklift35 ton Diesel ForkliftFour Wheel Drive Forklift

- Electric Forklift

-

- 3.8ton FB38LE Low Voltage Lithium Battery Forklift3.5ton FB35LE Low Voltage Lithium Battery Forklift3.5ton Low Voltage FB35LE-e Lithium Battery forklift3 ton Low Voltage FB30LE Lithium Battery Forklift12t Lithium-Battery-forklift12t Electric Forklift Truck8t Electric Forklift10t electric forklift truck25ton Lithium Battery Forklift7ton Electric Forklift16ton Lithium Battery forklift2 Ton Electric Forklift1.8 Ton Electric Forklift6 Ton Electric Forklift1.5 Ton Electric Forklift1 Ton Electric Forklift2.5 Ton Electric Forklift3.5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift1.6 Ton Three Wheel Forklift2 Ton Three Wheel Forklift

- Rough Terrain Forklift

-

- Supply 4-wheel Steer Rough Terrain Forklift7 Ton All Rough Terrain ForkliftFD25RTC4 Rough Terrain Forklift TruckFD35RT4 3.5T Rough Terrain ForkliftFD30RT4 3t Rough Terrain ForkliftFD35RT2 3.5t Rough Terrain ForkliftFD30RT2 3t Rough Terrain ForkliftFLIFT brand 3ton 3.5ton all rough terrain forklift for sale3 Ton Terrain Forklift

- Pallet stacker & Pallet truck

-

- DGX15 1.5t Electric Pallet StackerDGX12 1.2t Electric Pallet StackerMCC16 1.6t Man Mount Three-way StackerDGXC1530 1.5t Outdoor Electric Pallet StackerDGXC15 1.5t Electric Pallet StackerCTX18 1.8t Electric Pallet Truck JackDGX1520 1.5t Electric Pallet StackerDGX1230-walking-type-electric-pallet-stackerDGX1225 1200kg Electric Pallet StackerDGX1220 1.2t Walking Type Electric StackerCTXF20 2t Paper Roll/Wire Pallet TruckDGXA0420 0.4t Battery Indoor Counterbalanced StackerDGXB1020 1t outdoor counterbalanced stackerDGXC1520 1.5t Rough Terrain StackerCTXJ15 1.5t Electric Pallet TruckCTXA20 2t Rough-Terrain-Pallet-TruckCTXZ20 2t Electric Pallet TruckCTX20 2t Elecric Pallet Truck1.5 Ton Handling Electric Pallet Truck2 Ton Reach Forklift1.5 Ton Reach Forklift2 Ton Electric Pallet TruckSemi-electric Pallet Stacker3-Way Pallet StackerSide loading forklift truck4 direction reach truckElectric Tow Tractor 2t

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight StackerProfessional Walking Type Electric Stacker with Special Attachment1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker4t QDD40 Seated type Electric TractorQDD60 Seated Type Fully Electric Tractor3t QDD30C Electric Tractor with Turning Radius 1545mm2t CQD20A Electric Simple Type Reach Forklift Truck1.5t CQD15A Simple Type Electric Reach forklift Truck5t Convertible Seated Electric Flat Truck3t CBD30Z Electric Vehicle Transfer Truck1.5t CDD15Y Electric Pallet Stacker (Rough Terrain)1t CXD10-45 Electric High Lift-Order Picker2t CQD20S-60 Four-way Walking Type Reach Forklift TruckCDD10A/15A Walking Type Fully Electric Pallet Stacker3t QDD30A Standing Type Electric Tractor1t CSD10 Man Mount Three-way Stacker1.5t AGV type CDD15J-16 Electric Pallet StackerCBD80 8t Electric Pallet Stacker6t CBD60 Electric Pallet StackerCBD120 1.2t Electric Pallet Stacker2t CDD20D-30 Walking type Electric Pallet StacckerCDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper FixtureFixed Short Arm non-sideshiftingnon-sideshiftingFixed Short Arm non-sideshiftingNon-sideshiftingHinged ForksCaton ClampRotatornon-SideshiftingTire ClampsPusherTurning Fork Clampsnon-sideshiftingLog HolderSideshiftingBroke Paper ClampsSideshiftingSideshiftingSingleLoad StabilizerFork PositionersSingle Double Pallet Handler

Forklift safety operation specifications

Date: 2024-08-20 View:

Forklift Safe Operation Guide - Do's and don 'Ts?

Forklift as a key industrial equipment, its operation is directly related to the safety of personnel and cargo.

This article details the safety norms and prohibited behaviors in the operation of forklift trucks,

whether novice or veteran, please read patiently to ensure that every operation can be safe and correct.

I、Forklift safety operation specifications

Prohibited Conduct

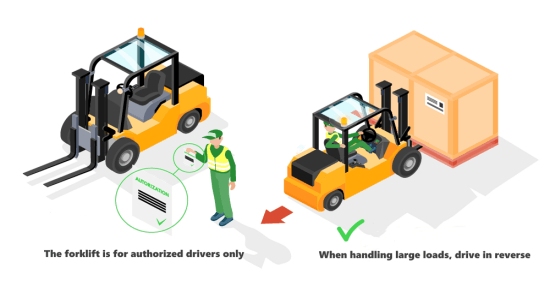

l It is strictly prohibited to operate a forklift without professional training, competency verification or authorization.

l It is strictly prohibited to wear personal protective equipment that does not meet safety standards.

l Forklifts and auxiliary equipment that are faulty or have not been properly maintained are prohibited.

l Do not operate the controls outside the driver's room unless the equipment is specifically designed for external operation.

l Do not stand next to the controls or reach outside the driver's room to operate or touch cargo.

l The forklift should not be used on uneven ground that has not been confirmed as suitable for driving.

l Non-professionals are prohibited from attempting to repair the forklift,

and all repairs should be carried out by professional maintenance engineers.

l It is strictly prohibited to operate the forklift under the influence of alcohol and drugs.

l When operating the forklift, do not use a mobile phone or other handheld devices that may distract you.

l Accessories that are not certified or authorized shall not be used in forklifts

unless their rated capacity has been reduced in writing by a qualified person,

authorized dealer, or manufacturer.

.png)

Must be performed

l Perform daily pre-shift forklift safety checks to ensure equipment is in good condition.

l Report any defects or anomalies to immediate supervisor.

l Clear and verify that work paths are clear and obstructions avoided.

l When operating, should start and stop smoothly, avoid rapid acceleration or sudden braking.

l Always observe the surrounding environment and driving direction, confirm the safety before moving the forklift.

l Pay special attention to the movement of pedestrians and take preventive driving measures to reduce sudden stops and violent braking.

l During driving, the fork should be properly lowered to a safe height to increase stability

and prevent ground wear, while maintaining ground clearance to ensure flexibility.

l When driving on wet, icy, slippery or soft surfaces, you should be especially cautious and slow down appropriately to ensure safety.

II、Safety codes for loading cargo

Prohibited conduct

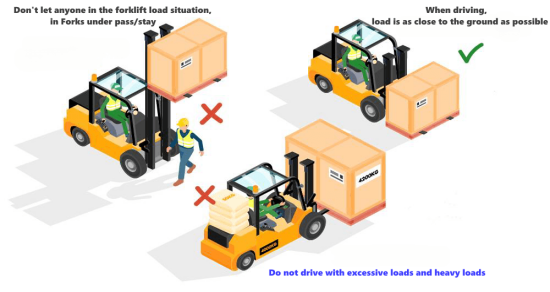

l Do not lift more than the rated load capacity of the forklift.

l Do not move goods that are damaged in appearance, unstable, or placed on damaged pallets.

l Do not use accessories to lift goods without professional training, certification and authorization.

l It is forbidden to ignore obstructed sight when carrying heavy goods.

l When the forklift design does not explicitly allow the carrying of lifting loads, such operations are strictly prohibited.

l Before leaving the forklift, ensure that the goods have been put down smoothly. Do not lift the goods.

l When carrying goods, the fork arm must be fully inserted under the goods to ensure stability.

Must carry out

- Before lifting, thoroughly evaluate the cargo, checking its weight, dimensions, load center and overall safety.

- Make sure the pallets are intact and comply with floor load limits to prevent accidents.

- Have a clear idea of the total weight of a fully loaded forklift and

- check the safe working load (SWL) of the shelves to ensure they are not overrun.

- Keep the load free from obstructing the line of sight. If the line of sight is obstructed,

- it should be operated in reverse and facing the direction of travel.

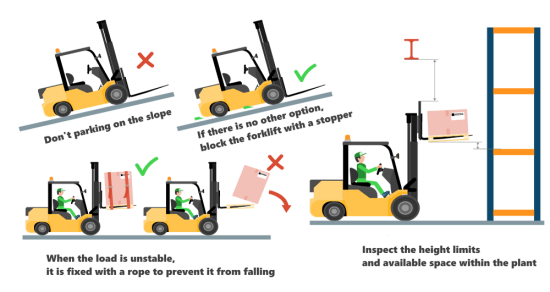

- Ensure that there is sufficient clearance between the forklift and the cargo, including overhead space, in case of collision.

- Verify cargo stability to ensure safe lifting and prevent slippage or tipping.

- Use the lever for smooth operation to avoid scram stops and starts.

- Carry the cargo as close to the ground as possible to improve stability and reduce risk.

- The fork should be placed accurately at the bottom of the load, near the center of gravity,

- to prevent the offset from causing the load to tilt and slide off when lifted or moved.

- The lifting operation must be carried out after the forklift has stopped completely to ensure safety.

3. Safety specifications for ramp operation

Prohibited items

l Flameout sliding: It is strictly prohibited to flameout sliding on the ramp to prevent loss of control and slide caused by loss of power.

l Overload driving: strictly abide by the forklift load limit, never overload on the ramp to ensure the stability of the vehicle.

l Sharp turns: Avoid sharp turns on ramps to reduce the impact of centrifugal force on vehicle stability.

l Parking at will: In non-emergency situations,

it is strictly prohibited to park on the ramp to prevent the vehicle from sliding down due to gravity.

Must be performed

l Select appropriate accessories: For unusual or wide cargo,

specially designed accessories should be used for lifting to ensure stable transportation.

l Slow down: when driving on the ramp, be sure to slow down the speed, maintain a constant speed,

avoid rapid acceleration and sudden braking,and prevent the vehicle from losing control and the goods from slipping off.

l Adjust the center of gravity of the vehicle: before going uphill,

reasonably adjust the center of gravity of the forklift according to the weight and distribution of the goods

to ensure the balance of the vehicle and prevent rollover and out of control.

l Correct orientation: Ensure that when the forklift is loaded uphill or downhill, the fork faces the top of the slope to enhance stability.

l Safe unloading: Reduce the load at an appropriate speed to ensure a smooth process and prevent damage to the cargo or injury to personnel.

l Qualification Confirmation: Before operation, confirm that you have received proper training, have a valid certificate,

and have the operation authorization under the conditions of use of the ramp and accessories.

l Tilt adjustment (if applicable) : Adjust the tilt of the forklift according to the slope,

and the fork can be adjusted appropriately to assist stability when going downhill, but is not used to "clear the ground".

l Correct use of brakes: when going uphill, gently step on the brakes to control the speed,

downhill is more cautious, using the delicate balance of brakes and speed to maintain safe driving.

Fourth, forklift parking safety specifications

Prohibited items

l No random slope parking: in non-emergency situations, forklift trucks are prohibited to park on the slope; When parking in an emergency,

the wheel must be fixed to prevent sliding.

l Do not park in dangerous areas: The forklift is strictly forbidden to park in any area that may cause harm to the forklift or the surrounding environment,

such as the fire danger area, the storage area of flammable and explosive materials, and the high temperature area.

l Prohibit blocking traffic parking: When the forklift truck is parked,

it must be ensured that it does not impede the normal passage of other vehicles and pedestrians,

and it is prohibited to park in the place that blocks traffic.

l Soft ground parking prohibited: Forklift trucks should be parked on a solid and smooth ground,

and it is prohibited to park in soft, muddy, pothole or easy to slide on the ground, in order to prevent tilt or tipping accidents.

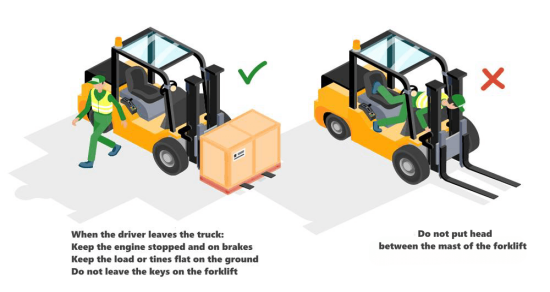

l No running parking: Except for special emergency situations (such as emergency maintenance),

the engine must be turned off and the key must be taken away when the forklift is parked.

No running parking is prohibited to prevent unauthorized start or accidents.

l No suspended fork parking: When the forklift is parked, the fork must be completely lowered to the ground, the fork tip contacts the ground,

and the fork is forbidden to park in the air to ensure the stability and safety of the forklift.

Must-dos

l The forklift must be parked in a designated safe area, ensuring that the ground is level and gradient-free.

l When parked, the forklift column should be tilted forward to a safe position with the fork fully lowered to a low point

and the fork tip lightly touching the ground to enhance stability.

l After parking, immediately apply the parking brake, put the shift lever in neutral,

turn off the engine and remove the key to ensure that the forklift is in a fully locked position.

l Store the keys or other starting equipment properly in a safe,

designated storage location to prevent unauthorized use.

5. Safety specifications for forklift carriers

Prohibited items

l It is strictly prohibited to use forklift forks, pallets or any part not designed for carrying people.

l Do not move or turn the forklift while carrying people.

l It is strictly forbidden to walk under the raised fork teeth or cargo to avoid the risk of falling.

l When using a forklift on a non-integrated work platform,

it must be supervised by a special person and used only under special circumstances, with strict recording control.

l When the forklift is not designed to carry passengers, it is strictly prohibited to carry passengers;

Even if there is a designated seat and seat belt, it must not violate its designed purpose.

Must-dos

l When it is necessary to use the work platform to carry people,

the integrated platform should be preferred to ensure safety and stability.

l The use of non-integrated platforms must be strictly supervised to ensure operator and worker safety,

with detailed documented controls in place for special cases.

l The forklift operator must maintain full control of the forklift at all times

while the worker is standing on the platform to ensure that any operation is carried out within a safe range.

.png)