- Diesel Forklift

-

- 4.5 Ton Diesel Forklift48 Ton Diesel Forklift3 Ton Diesel Forklift3.5 Ton Diesel Forklift2.5 Ton Diesel Forklift33 Ton Diesel Forklift15 Ton Diesel Forklift10 Ton Diesel Forklift8 Ton Diesel Forklift4 Ton Diesel Forklift6 Ton Diesel Forklift2 Ton Diesel Forklift1 Ton Diesel Forklift1.8 Ton Diesel Forklift1.5 Ton Diesel Forklift6 Ton Diesel Forklift35 ton Diesel ForkliftFour Wheel Drive Forklift

- Electric Forklift

-

- 3.8ton FB38LE Low Voltage Lithium Battery Forklift3.5ton FB35LE Low Voltage Lithium Battery Forklift3.5ton Low Voltage FB35LE-e Lithium Battery forklift3 ton Low Voltage FB30LE Lithium Battery Forklift12t Lithium-Battery-forklift12t Electric Forklift Truck8t Electric Forklift10t electric forklift truck25ton Lithium Battery Forklift7ton Electric Forklift16ton Lithium Battery forklift2 Ton Electric Forklift1.8 Ton Electric Forklift6 Ton Electric Forklift1.5 Ton Electric Forklift1 Ton Electric Forklift2.5 Ton Electric Forklift3.5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift1.6 Ton Three Wheel Forklift2 Ton Three Wheel Forklift

- Rough Terrain Forklift

-

- Supply 4-wheel Steer Rough Terrain Forklift7 Ton All Rough Terrain ForkliftFD25RTC4 Rough Terrain Forklift TruckFD35RT4 3.5T Rough Terrain ForkliftFD30RT4 3t Rough Terrain ForkliftFD35RT2 3.5t Rough Terrain ForkliftFD30RT2 3t Rough Terrain ForkliftFLIFT brand 3ton 3.5ton all rough terrain forklift for sale3 Ton Terrain Forklift

- Pallet stacker & Pallet truck

-

- DGX15 1.5t Electric Pallet StackerDGX12 1.2t Electric Pallet StackerMCC16 1.6t Man Mount Three-way StackerDGXC1530 1.5t Outdoor Electric Pallet StackerDGXC15 1.5t Electric Pallet StackerCTX18 1.8t Electric Pallet Truck JackDGX1520 1.5t Electric Pallet StackerDGX1230-walking-type-electric-pallet-stackerDGX1225 1200kg Electric Pallet StackerDGX1220 1.2t Walking Type Electric StackerCTXF20 2t Paper Roll/Wire Pallet TruckDGXA0420 0.4t Battery Indoor Counterbalanced StackerDGXB1020 1t outdoor counterbalanced stackerDGXC1520 1.5t Rough Terrain StackerCTXJ15 1.5t Electric Pallet TruckCTXA20 2t Rough-Terrain-Pallet-TruckCTXZ20 2t Electric Pallet TruckCTX20 2t Elecric Pallet Truck1.5 Ton Handling Electric Pallet Truck2 Ton Reach Forklift1.5 Ton Reach Forklift2 Ton Electric Pallet TruckSemi-electric Pallet Stacker3-Way Pallet StackerSide loading forklift truck4 direction reach truckElectric Tow Tractor 2t

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight StackerProfessional Walking Type Electric Stacker with Special Attachment1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker4t QDD40 Seated type Electric TractorQDD60 Seated Type Fully Electric Tractor3t QDD30C Electric Tractor with Turning Radius 1545mm2t CQD20A Electric Simple Type Reach Forklift Truck1.5t CQD15A Simple Type Electric Reach forklift Truck5t Convertible Seated Electric Flat Truck3t CBD30Z Electric Vehicle Transfer Truck1.5t CDD15Y Electric Pallet Stacker (Rough Terrain)1t CXD10-45 Electric High Lift-Order Picker2t CQD20S-60 Four-way Walking Type Reach Forklift TruckCDD10A/15A Walking Type Fully Electric Pallet Stacker3t QDD30A Standing Type Electric Tractor1t CSD10 Man Mount Three-way Stacker1.5t AGV type CDD15J-16 Electric Pallet StackerCBD80 8t Electric Pallet Stacker6t CBD60 Electric Pallet StackerCBD120 1.2t Electric Pallet Stacker2t CDD20D-30 Walking type Electric Pallet StacckerCDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper FixtureFixed Short Arm non-sideshiftingnon-sideshiftingFixed Short Arm non-sideshiftingNon-sideshiftingHinged ForksCaton ClampRotatornon-SideshiftingTire ClampsPusherTurning Fork Clampsnon-sideshiftingLog HolderSideshiftingBroke Paper ClampsSideshiftingSideshiftingSingleLoad StabilizerFork PositionersSingle Double Pallet Handler

liquid cooled thermal management system for lithium ion battery forklift

Date: 2025-04-03 View:

What is liquid cooling system for lithium-ion battery?

Lithium-ion battery liquid cooling system is an important part of the battery thermal management system (TMS).

Its core principle is to use antifreeze as a heat transfer medium and achieve battery temperature regulation through water circulation.

The system mainly has the following three functions:

Temperature uniformity function:

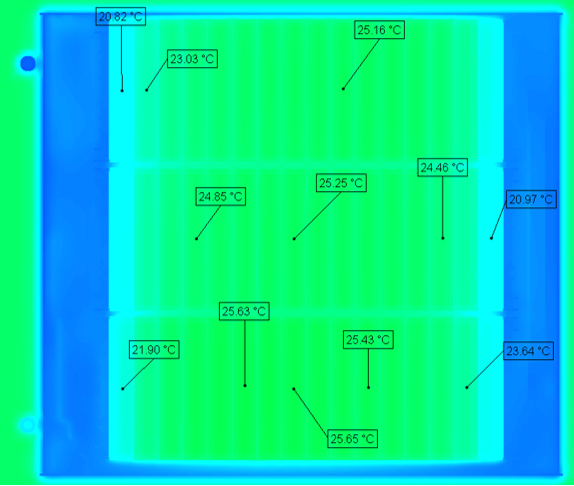

The water circulation in the liquid-cooled battery pack can ensure that the temperature of each battery cell is uniform.

During the battery charging and discharging process, the temperature difference between the cells will affect the overall performance of the battery.

Through temperature uniformity control, the battery's endurance can be effectively improved, and the battery can be protected to avoid performance degradation caused by local overheating.

Cooling function:

When the battery is working or fast charging, a lot of heat will be generated. If the heat is not dissipated in time, the battery temperature will continue to rise, affecting its performance and safety.

The lithium-ion battery liquid cooling system can accurately control the battery to work in a suitable temperature range by adjusting the cooling water pump and compressor cooling, effectively suppressing the battery temperature rise and ensuring stable battery operation.

.jpg)

Heating function:

In a low temperature environment, the performance of the battery will drop significantly.

To this end, the lithium-ion battery liquid cooling system can be equipped with a WPTC water heater to heat the battery coolant and increase the battery temperature so that it can work normally in a low-temperature environment, achieve a 1C charge and discharge rate, and extend the battery life.

In addition, in terms of motor electronic control thermal management (ATS), the vehicle controller can adjust the water cooling heat dissipation cycle to ensure that the motor and electronic control work within the appropriate temperature range, and work in conjunction with the lithium-ion battery liquid cooling system to jointly ensure the stable operation of key components of the electric forklift.

Advantages of lithium-ion battery

liquid cooling system on electric forklifts

It uses antifreeze with high specific heat capacity as the heat conduction medium, which can accurately achieve temperature equalization, cooling and heating functions.

Excellent thermal conductivity can quickly take away the heat generated by the battery operation, ensure that the temperature of each battery cell is uniform, and avoid local overheating.

Under complex working conditions, whether it is a high temperature or low temperature environment, the battery can always be in the best working state, greatly improving the efficiency, stability and durability of the battery, extending the battery life, optimizing the forklift endurance performance, and ensuring the efficient and reliable operation of the forklift.

.png)