- Diesel Forklift

-

- 4.5 Ton Diesel Forklift48 Ton Diesel Forklift3 Ton Diesel Forklift3.5 Ton Diesel Forklift2.5 Ton Diesel Forklift33 Ton Diesel Forklift15 Ton Diesel Forklift10 Ton Diesel Forklift8 Ton Diesel Forklift4 Ton Diesel Forklift6 Ton Diesel Forklift2 Ton Diesel Forklift1 Ton Diesel Forklift1.8 Ton Diesel Forklift1.5 Ton Diesel Forklift6 Ton Diesel Forklift35 ton Diesel ForkliftFour Wheel Drive Forklift

- Electric Forklift

-

- 3.8ton FB38LE Low Voltage Lithium Battery Forklift3.5ton FB35LE Low Voltage Lithium Battery Forklift3.5ton Low Voltage FB35LE-e Lithium Battery forklift3 ton Low Voltage FB30LE Lithium Battery Forklift12t Lithium-Battery-forklift12t Electric Forklift Truck8t Electric Forklift10t electric forklift truck25ton Lithium Battery Forklift7ton Electric Forklift16ton Lithium Battery forklift2 Ton Electric Forklift1.8 Ton Electric Forklift6 Ton Electric Forklift1.5 Ton Electric Forklift1 Ton Electric Forklift2.5 Ton Electric Forklift3.5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift5 Ton Electric Forklift3 Ton Electric Forklift4.5 Ton Electric Forklift1.6 Ton Three Wheel Forklift2 Ton Three Wheel Forklift

- Rough Terrain Forklift

-

- Supply 4-wheel Steer Rough Terrain Forklift7 Ton All Rough Terrain ForkliftFD25RTC4 Rough Terrain Forklift TruckFD35RT4 3.5T Rough Terrain ForkliftFD30RT4 3t Rough Terrain ForkliftFD35RT2 3.5t Rough Terrain ForkliftFD30RT2 3t Rough Terrain ForkliftFLIFT brand 3ton 3.5ton all rough terrain forklift for sale3 Ton Terrain Forklift

- Pallet stacker & Pallet truck

-

- DGX15 1.5t Electric Pallet StackerDGX12 1.2t Electric Pallet StackerMCC16 1.6t Man Mount Three-way StackerDGXC1530 1.5t Outdoor Electric Pallet StackerDGXC15 1.5t Electric Pallet StackerCTX18 1.8t Electric Pallet Truck JackDGX1520 1.5t Electric Pallet StackerDGX1230-walking-type-electric-pallet-stackerDGX1225 1200kg Electric Pallet StackerDGX1220 1.2t Walking Type Electric StackerCTXF20 2t Paper Roll/Wire Pallet TruckDGXA0420 0.4t Battery Indoor Counterbalanced StackerDGXB1020 1t outdoor counterbalanced stackerDGXC1520 1.5t Rough Terrain StackerCTXJ15 1.5t Electric Pallet TruckCTXA20 2t Rough-Terrain-Pallet-TruckCTXZ20 2t Electric Pallet TruckCTX20 2t Elecric Pallet Truck1.5 Ton Handling Electric Pallet Truck2 Ton Reach Forklift1.5 Ton Reach Forklift2 Ton Electric Pallet TruckSemi-electric Pallet Stacker3-Way Pallet StackerSide loading forklift truck4 direction reach truckElectric Tow Tractor 2t

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight StackerProfessional Walking Type Electric Stacker with Special Attachment1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker4t QDD40 Seated type Electric TractorQDD60 Seated Type Fully Electric Tractor3t QDD30C Electric Tractor with Turning Radius 1545mm2t CQD20A Electric Simple Type Reach Forklift Truck1.5t CQD15A Simple Type Electric Reach forklift Truck5t Convertible Seated Electric Flat Truck3t CBD30Z Electric Vehicle Transfer Truck1.5t CDD15Y Electric Pallet Stacker (Rough Terrain)1t CXD10-45 Electric High Lift-Order Picker2t CQD20S-60 Four-way Walking Type Reach Forklift TruckCDD10A/15A Walking Type Fully Electric Pallet Stacker3t QDD30A Standing Type Electric Tractor1t CSD10 Man Mount Three-way Stacker1.5t AGV type CDD15J-16 Electric Pallet StackerCBD80 8t Electric Pallet Stacker6t CBD60 Electric Pallet StackerCBD120 1.2t Electric Pallet Stacker2t CDD20D-30 Walking type Electric Pallet StacckerCDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper FixtureFixed Short Arm non-sideshiftingnon-sideshiftingFixed Short Arm non-sideshiftingNon-sideshiftingHinged ForksCaton ClampRotatornon-SideshiftingTire ClampsPusherTurning Fork Clampsnon-sideshiftingLog HolderSideshiftingBroke Paper ClampsSideshiftingSideshiftingSingleLoad StabilizerFork PositionersSingle Double Pallet Handler

Lithium ion battery forklift for cold storage fast charging Liquid-Cooled Thermal Management System

Date: 2025-02-26 View:

Electric Forklifts in Cold Storage:

Challenges and Solutions

The demand for cold storage facilities is rising due to the growth of industries such as food distribution, pharmaceuticals, and e-commerce.

As companies seek to improve efficiency and sustainability, electric forklifts have become a preferred choice for material handling.

However, operating electric forklifts in cold storage environments presents unique challenges, particularly related to battery performance and maintenance.

This article explores these challenges and highlights how advanced solutions, including CATL original batteries with liquid-cooled thermal management systems, are transforming cold storage operations.

Challenges of Electric Forklifts in Cold Storage

1. Battery Performance and Efficiency

Cold temperatures can significantly impact battery efficiency, reducing capacity and increasing charging time.

In extreme cold conditions (-30°C or lower), conventional lithium-ion and lead-acid batteries struggle to maintain optimal performance, leading to frequent downtime and decreased productivity.

2. Condensation and Moisture Buildup

The transition between freezing and warmer areas can cause condensation to form on forklifts, potentially leading to electrical malfunctions and corrosion.

This issue is especially problematic for battery terminals and sensitive electronic components.

3. Reduced Lifespan of Batteries

Frequent exposure to low temperatures accelerates battery degradation, leading to shorter operational lifespans.

Standard batteries may require more frequent replacements, increasing maintenance costs and disrupting workflow.

4. Longer Charging Times

Cold environments slow down the chemical reactions inside batteries, leading to extended charging times.

This delay can affect productivity, requiring additional backup equipment to maintain operations.

Solutions for Efficient Cold Storage Operations

1. Advanced Battery Technology

The CATL original battery, designed to function from +60°C to -30°C, offers a game-changing solution.

Unlike conventional batteries, this advanced lithium-ion battery maintains high efficiency even in freezing temperatures, ensuring consistent performance without significant power loss.

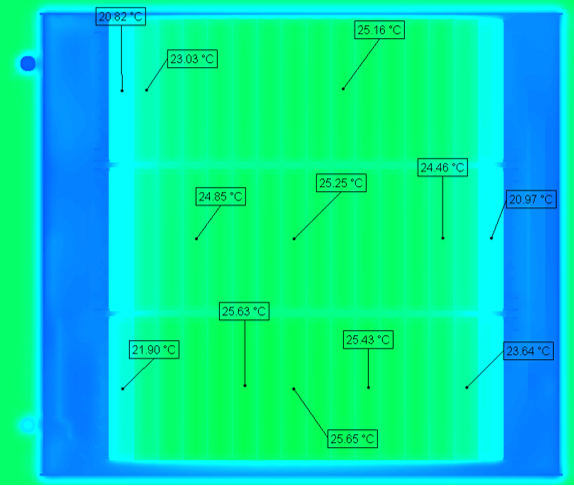

2. Liquid-Cooled Thermal Management System

Temperature regulation is key to enhancing battery longevity and efficiency.

CATL’s liquid-cooled thermal management system helps stabilize battery temperature, preventing extreme fluctuations and minimizing the impact of cold conditions.

This system ensures optimal thermal balance, reducing degradation and maintaining energy efficiency.

3. Insulated and Heated Storage Areas

Implementing battery storage areas with controlled temperature zones can help extend battery life and improve reliability.

Heated battery compartments or storage racks within the facility can prevent excessive cooling of batteries during idle periods.

4. Fast Charging Capabilities

(1).jpg)

Utilizing rapid-charging stations designed for cold storage applications can help mitigate longer charging times.

CATL’s battery technology enables efficient energy transfer, allowing forklifts to return to operation quicker than those with traditional batteries.

.png)